About us Diamonds Contact Pricelist Guestbook Links

Natural Diamonds vs. Enhanced Diamonds

Whether to buy a natural diamond or a treated or

enhanced diamond....

Diamonds can also be produced synthetically in a HPHT method which approximately

simulates the conditions in the Earth's mantle.

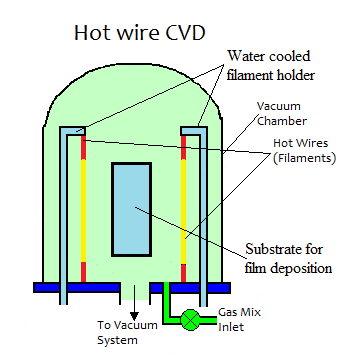

An alternative, and completely different growth technique is chemical vapor

deposition (CVD). Several non-diamond materials,

which include cubic zirconia and silicon carbide and are often called diamond

simulants, resemble diamond in appearance and

many properties. Special gemological techniques have been developed to

distinguish natural, synthetic diamonds and diamond simulants.

Natural Diamonds

Made from carbon, diamonds are the hardest known substance to man and are both a

naturally occurring and manufactured abrasive. Natural diamonds

form at high pressure high temperature conditions existing between 85 to 125

miles in the earth’s mantle. It takes a diamond 1 to 3 billion years

to form beneath the earth. Once formed, a diamond travels to the earth’s surface

via streams of molten rock. Throughout this process,

natural diamonds acquire inclusions and or flaws within them that give them

their own unique “fingerprint”.

Diamonds can be purchased in various sizes (carats), shapes, colors, and

clarities. Natural diamonds are preferred over enhanced or treated diamonds

because of their rarity and individual fingerprint. No two natural diamonds in

the world are identical; each one is unique whether it’s because of

its color or clarity or both combined.

Enhanced or Treated Diamonds

The term “enhanced” may sound like a positive feature, however, any diamond that

has been enhanced has been treated and altered from its

natural condition to artificially improve its appearance. If you decide to

purchase an “enhanced” diamond, find out what kind of treatments

have been used and how they might affect the value of the diamond. You should

also be concerned with the long term care and appearance these

enhancement treatments may have on the diamond, as enhancements sometimes result

in discoloration or cracks in the diamond.

Enhanced diamonds, unlike high quality natural diamonds are natural diamonds

that have had very specific treatments done to them to improve

their characteristics, or their natural “flaws”. One type of treatment is laser

drilling, which is a process that removes minor inclusions

in a diamond to produce a clarity enhanced diamond. This process will typically

create lines that resemble tiny trails, which are visible

under side-view magnification. The laser may dissipate the imperfection, or

chemicals may be injected into the resulting tunnel to bleach

away the color. This is a more permanent process than fracture filling. However,

it is highly debated whether or not this process damages

the integrity of the diamonds, thereby decreasing the value of clarity enhanced

diamonds in the long term.

Fracture filling is a treatment that adds a glass-like resin material to a

natural diamond to close small cracks. Since the filling has

the same optical illusion and refraction index as a natural diamond, it’s nearly

impossible to detect the “repair” to the flaws.

Fracture filling is not a permanent treatment as heat from future repairs,

cleanings, and even sunlight can erode the filler or possibly

darken its color, making the diamond less valuable as time goes on.

One other type of enhancement treatment is called HPHT (high-pressure

high-temperature). HPHT is a treatment process that General Electric

developed to permanently change the color of a diamond. First used to turn

yellowish diamonds into “fancy” colored diamonds, this process

is commonly used to turn yellow or brown diamonds into colorless diamonds to be

sold at a significantly higher prices. HPHT involves putting

a diamond into a pressure chamber and squeezing it at high pressure and high

temperature for a short amount of time. Although some feel that

this treatment should be considered a standard technique and claim that this

process is just finishing the job that nature started, the Federal

Trade Commission feels that it is an artificial process and requires that HPHT

be disclosed. When HPHT treatment is detected in a diamond,

the Gemological Institute of American (GIA) notes it on their reports as “HPHT

Annealed” or “Artificially Irradiated” and insists that such

diamonds be laser-inscribed with the same designation. A diamond that has been

enhanced by GE will be inscribed with the symbol “GE POL”.

Detecting Enhanced or Treated Diamonds

There are different ways to detect if a diamond has had clarity enhancement

treatments done to it. As mentioned above, laser drilling result

s in very thin, white lines or tunnels within the diamond that do not follow the

pattern of the loose diamond. When fracture filling is used,

the diamond may appear flawless when viewed from the top, but careful

examination from the sides or other angles may reveal flashes of color

that disrupt the pattern of facets in the diamond. Fracture filled diamonds may

also have air bubbles trapped within them. Because these hints

are only visible from the sides, it is very important to examine the diamond

closely and preferable as a loose diamond rather than set

into a diamond ring setting.

The Controversy About Enhanced or Treated Diamonds

Due to the controversial nature of diamond treatments within the industry, the

CIBJO (World Jewelry Confederation), the United Stated

Federal Trade Commission, and the GIA all require the disclosure of all diamond

treatments at the time of sale. Without this disclosure,

consumer confidence in diamond purchasing would be significantly damaged.

Synthetic diamonds

Synthetic diamond (also known as cultured diamond or

cultivated diamond) is diamond produced in an artificial process, as opposed

to natural diamonds, which are created by geological processes. Synthetic

diamond is also widely known as HPHT diamond or CVD diamond

after the two common production methods (referring to the high-pressure

high-temperature and chemical vapor deposition crystal

formation methods, respectively). While the term synthetic is associated by

consumers with imitation products, artificial diamonds

are made of the same material (pure carbon, crystallized in isotropic 3D form).

In the U.S., the Federal Trade Commission has

indicated that the alternative terms laboratory-grown and laboratory-created

"would more clearly

communicate the nature of the stone".

Numerous claims of diamond synthesis were documented between 1879 and 1928; most

of those attempts were carefully analyzed but

none were confirmed. In the 1940s, systematic research began in the United

States, Sweden and the Soviet Union to grow diamonds

using CVD and HPHT processes. The first reproducible synthesis was reported

around 1953. Those two processes still dominate the

production of synthetic diamond. A third method, known as detonation synthesis,

entered the diamond market in the late 1990s.

In this process, nanometer-sized diamond grains are created in a detonation of

carbon-containing explosives. A fourth method,

treating graphite with high-power ultrasound, has been demonstrated in the

laboratory, but currently has no commercial application.

The properties of synthetic diamond depend on the details of the manufacturing

processes; however, some synthetic diamonds

(whether formed by HPHT or CVD) have properties such as hardness, thermal

conductivity and electron mobility that are superior

to those of most naturally formed diamonds. Synthetic diamond is widely used in

abrasives, in cutting and polishing tools and

in heat sinks. Electronic applications of synthetic diamond are being developed,

including high-power switches at power stations,

high-frequency field-effect transistors and light-emitting diodes. Synthetic

diamond detectors of ultraviolet (UV) light or

high-energy particles are used at high-energy research facilities and are

available commercially. Because of its unique combination

of thermal and chemical stability, low thermal expansion and high optical

transparency in a wide spectral range, synthetic diamond

is becoming the most popular material for optical windows in high-power CO2

lasers and gyrotrons. It is estimated that 98% of industrial

grade diamond demand is supplied with synthetic diamonds.

.jpg)

"At Daems Diamonds, we want our clients to be educated about different types of

diamonds and diamond treatments so that they can feel confident

when purchasing their future loose diamonds. Most consumers and diamond

professionals feel that natural diamonds should not be

artificially treated in any significant manner. However, there are many

differing opinions about the controversy of enhanced or treated diamonds

vs. natural diamonds. As most gemological experts agree, Daems Diamonds

recommends purchasing natural certified diamonds and offers only 100% natural

and conflict-free diamonds. We do not sell any loose diamonds or diamond jewelry

that have been enhanced or treated in any way."

Marc Daems